TOMRA signed an agreement with the owners of Compac Holding Ltd (Compac) on October 11, 2016 to acquire 100 percent of the shares in the company. In this article, members of TOMRA and Compac management provide answers to key questions surrounding the acquisition.

TOMRA’s acquisition of Compac – questions and answers

TOMRA acquires New Zealand Sorting Machine Manufacturer Compac

TOMRA acquires New Zealand Sorting Machine Manufacturer Compac for NZD 70m.

TOMRA Systems ASA, has signed an agreement with the owners of Compac Holding Ltd (Compac) for 100 per cent of the shares in the company. Closing of the transaction is expected to take place during the first quarter of 2017, subject to approval by the New Zealand Overseas Investment Office.

10 reasons we should be inspecting your produce for internal defects

Following my previous blog post, Ten reasons to blemish grade, talking about external fruit grading, it seemed only natural to cover the importance of internal fruit grading next.

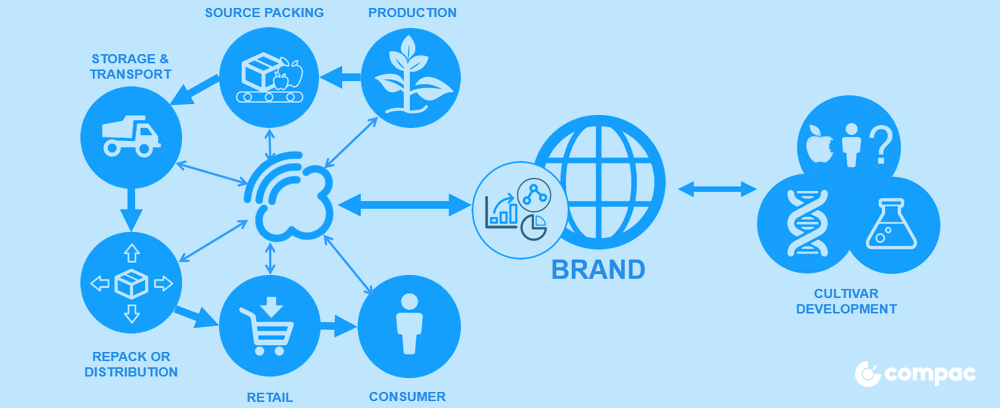

Consumer trends create huge opportunity for branded fresh produce

Retail branding gives your customers something to remember you by. While the fresh produce industry hasn’t always put a lot of emphasis on creating retail brands, this is changing rapidly. In fact, branded produce sales in the fresh produce sector are expected to reach almost US$7 billion by 2018 (a growth of $1.4 billion from 2013). So why the shift and why now?

Asia Fruit Logistica focuses on how technology is changing the supply chain

Every September, thousands of people from the fresh produce industry pour into the halls of Asia Fruit Logistica (AFL) in Hong Kong. This year’s show has smashed previous attendance records, marking a 22% increase on last year with over 11,000 visitors from 74 different countries.

Reviewing the 2016 Pacific Northwest cherry season

Following a busy season of installations and upgrades to existing customer lines earlier in the year, the 2016 Pacific Northwest (PNW) cherry is now wrapped up. Talk about a good season – high quality product and the 3rd largest packout ever achieved.

“It was one of the best seasons in recent history. Growing conditions were optimal; we had a good size crop with large fruit size. Consumers were very happy with fruit quality and their eating experience" – Andy Tudor, Director of Business Development, Zirkle Fruit Company.

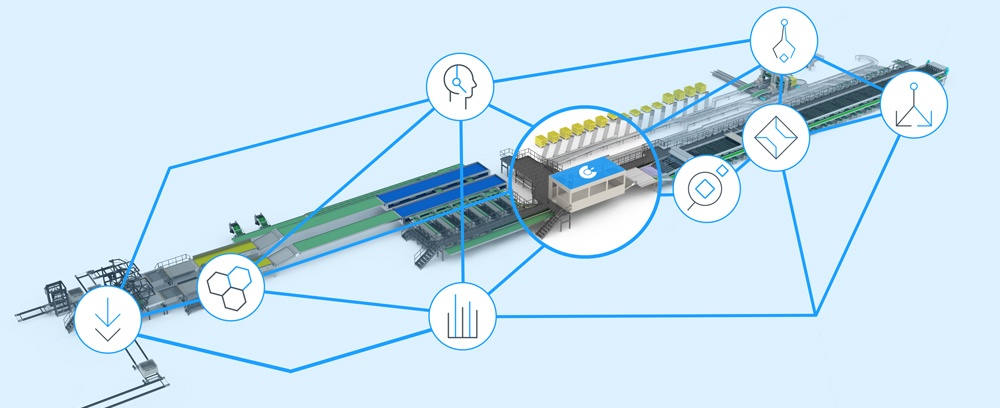

Integration: the fourth industrial revolution in the fresh produce industry

Packhouses are packing more produce, more efficiently, than they ever have before. These productivity gains have come about through bigger, better, and more sophisticated machines from a range of different vendors, with Compac leading the charge in sorting and inspection systems.

Spectrim the perfect combination of sophistication and simplicity for packhouses

It’s been almost a year since Spectrim was launched in the market and in that time we’ve seen real success from our customers who have invested in the platform.

Spectrim’s ability to “grade above the line” is where the operator and packhouse are seeing business value. What is the line? The line is the grade which the packhouse is looking to reach. This grade could be the minimum USDA standard required for packhouses, or it can be the grade their customer's demand – the standard in which their brand promises and their consumers expect.

When it comes to ‘ugly fruit’- beauty is only skin deep

We all know that when dealing with fresh produce we are dealing with mother nature. Weather conditions aren’t always perfect and therfore neither is some of the fruit. These so-called "ugly fruit" are a fact of life for growers. With light external defects, discoloration or misshapen, they may not be pretty, but they're still perfectly tasty, just as nutritious and until recently they weren’t available at the supermarket.

Fruit packing to packed lunch: the value of data in the fresh produce industry

The demand for fresh produce is ballooning worldwide. Packhouses are busier than they’ve ever been in order to meet increased demand, while continuing to offer a wide range of products of different sizes and levels of quality inside innovative packaging. Despite the increased volumes, end consumers still expect the quality of every fruit to be consistently high — and whether or not these expectations are met can make or break brands.