All-new cluster separating machine for cherries, which eliminates product damage, will be shown publicly for the first time at the international trade exhibition in Spain.

TOMRA FRESH FOOD TO UNVEIL NEW CASCADE SINGULATOR - "A GAME-CHANGER THAT WILL REVOLUTIONIZE THE CHERRY INDUSTRY" - AT FRUIT ATTRACTION EXHIBITION

Topics: News article, Equipment & Technology

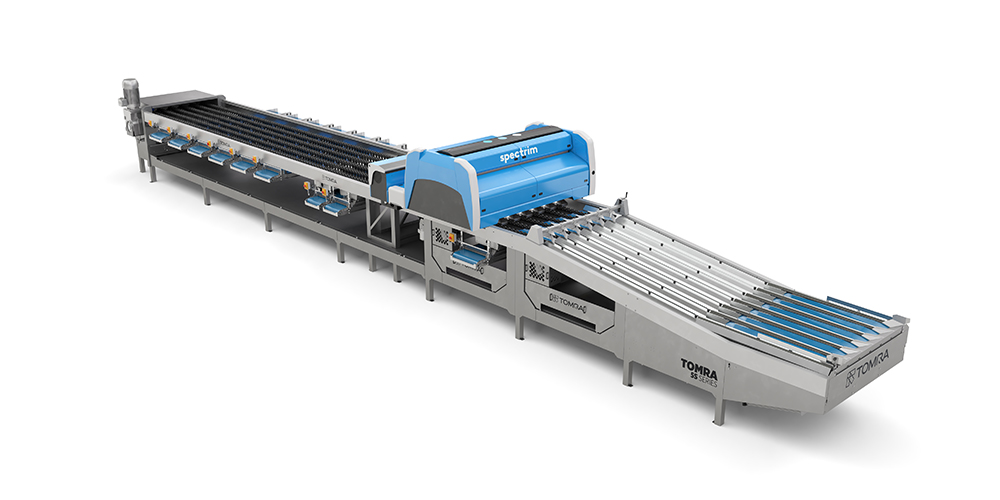

TOMRA Food sets new standards in grading accuracy with SmartGradeTM software on its SpectrimTM advanced industrial imaging platform

TOMRA Food introduces SmartGrade on its Spectrim platform. The new system puts the packhouse in complete control of grading with such accuracy that it is able to pack fruit to maximize sales by matching very precisely the specific requirements of the individual customers. It identifies each blemish and defect type, and maintains consistent grading performance even when there is high variability in the quality profile of incoming fruit batches. US-based packer Prima Frutta is an excellent example of how SmartGrade takes grading accuracy to an entirely new level, delivering significant improvements in efficiency, yields and profitability with all commodity types.

Topics: News article, Equipment & Technology

CUSTOMER TESTIMONIAL HMC FARMS, USA

Based in the heart of California’s Central (San Joaquin) Valley, cultivating 5,000 acres of peaches, plums, and nectarines, the tradition of family farming has been a part of the HMC Farms’ story since 1887. HMC Farms has spent generations innovating their growing and handling practices to ensure that they can reliably provide their customers with the simple pleasure of great tasting fruit.

Topics: Fruit, Customer testimonials, Equipment & Technology

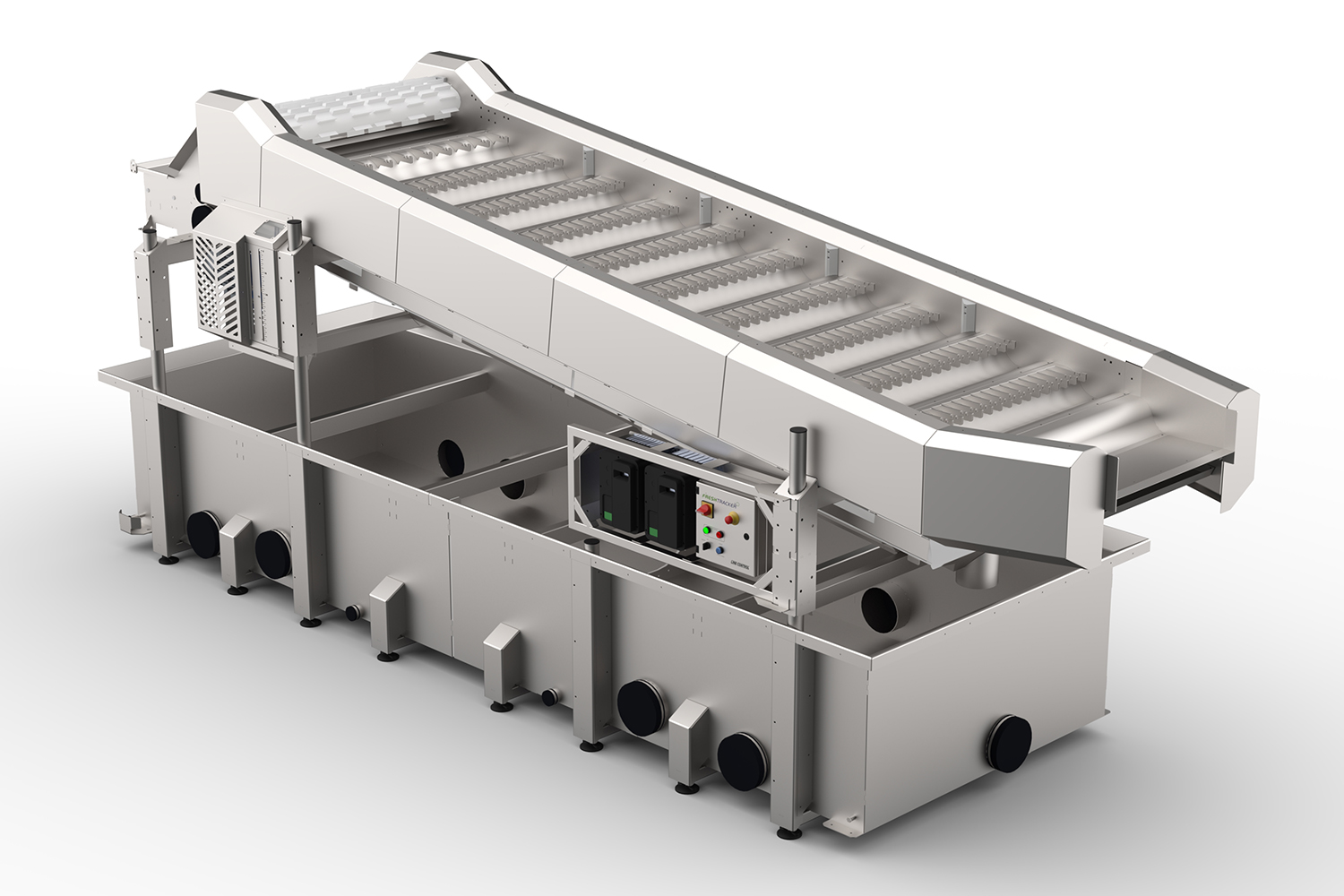

New Gentle Box Filler+ designed for delicate fruits combines Compac's trademark gentle handling with high throughput

Compac, part of the TOMRA Food family, extends its box filling platform offering with the new-generation Gentle Box Filler+ model developed specifically for the most delicate produce. It combines faster throughput with the industry-leading gentle handling that is the hallmark of Compac's original box filler design. The significantly higher throughput translates into more added value for the packer's operation due to the greater productivity, efficiency and flexibility, as well as a smaller initial investment – with the gentlest handling.

Topics: News article, Equipment & Technology

TOMRA VISUAL ASSIST, THE NEW AUGMENTED REALITY TOOL FOR REMOTE ASSISTANCE, MOBILIZES TOMRA'S GLOBAL EXPERTISE TO PROVIDE FAST AND EFFECTIVE SERVICE SUPPORT TO CUSTOMERS

TOMRA Visual Assist virtually places TOMRA's expert in front of the customer's machine, enabling a fast response and, during the COVID-19 pandemic, overcoming travel restrictions and addressing safety concerns.

Topics: News article, Equipment & Technology, Food Trends

Blog: Designing an Optimal Fruit Packhouse?

HOW TO AVOID CREATING A HOUSE OF HORRORS!

Building a packhouse is a massive undertaking both financially & emotionally. Here's how to focus investments on areas that affect SKU creation and throughput which can have a huge pay off over time. This blog will help you define and understand the 10-to-20-year operational life of your foundational equipment investments and to do it right the first time so as to avoid costly ad-hoc additions later.

Topics: Fruit, Equipment & Technology

TOMRA INSIGHT IS NOW AVAILABLE FOR THE FOOD INDUSTRY

Topics: News article, Equipment & Technology, Corporate News, Food Trends

Compac lanza su plataforma de clasificación de nueva generación para plantas de envasado, preparada para el futuro

Topics: News article, Equipment & Technology, Corporate News, Food Trends

Compac launches its next generation sorting platform designed to futureproof packhouse businesses

Topics: News article, Equipment & Technology, Corporate News, Food Trends

Compac overcomes challenges of pandemic to deliver full satisfaction and a successful cherry season to customers in Turkey and Uzbekistan

Compac, part of the TOMRA Food family, and its partners ICOEL and Sardas were confronted with unique challenges, as the COVID-19 pandemic hit just as they were preparing to ship and install three turnkey cherry grading and packing lines in Turkey and a fourth one in Uzbekistan. They overcame the unprecedented situation with countries under lockdown, travel restrictions and disruptions to goods transport logistics to complete the four projects right on schedule. This achievement required all the ingenuity of the teams involved in the installation, who were able to leverage Compac’s global supply chain and extreme operational flexibility. The four lines, equipped with Compac’s InVision2 electronic grading platform, were up and running for the beginning of the cherry season and they performed to the respective customers’ satisfaction. With their new Compac grading and packing lines, Perla Fruit, Karaali, Unifrutti in Turkey and Uz-Segang in Uzbekistan closed the season with resounding success, receiving positive feedback from their customers.

Topics: Fruit, News article, Customer testimonials, Equipment & Technology, Corporate News

.jpg)