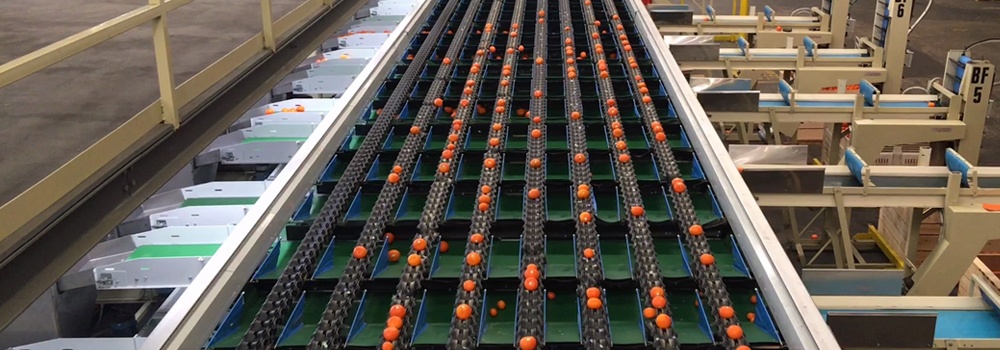

On the 23rd of March, Prime Minister Bill English officially opened EastPack’s new ‘super grader’ in Te Puke, New Zealand ahead of the start of this year’s kiwifruit harvest. The Washer Road site now has the largest automated kiwifruit grading and sorting line in the world, with 14 lanes and the ability to pack 100,000 trays per shift. This provides EastPack with capacity to pack more than 40 million trays of fruit across the business.

New Zealand Prime Minister pushes “Go” on Spectrim to start the kiwifruit season

A Time for change: Technology in the fresh produce industry

The fresh produce industry is facing challenges that only technology can help resolve. In an age where we’re all technology adopters, we barely bat an eyelid at the incredible technological achievements humans are making globally. But when we stop to take a look, we’re making huge advancements in all areas and the fresh produce industry is certainly no exception.

Compac and Tomra exhibiting together at Hort Connections 2017

Compac and TOMRA will be exhibiting at Hort Connections 2017 on 15 - 17 May, at the Adelaide Convention Centre. This show is exciting as it’s the first of two great things - it’s the first time PMA and AUSVEG have united to deliver a joint industry conference and trade show, and it’s also the first time Compac and Tomra have shared a booth in Australia.

Repackers are faced with changing customer demands

Fresh food contributes a healthy 30-60 percent of total grocery spending. It boosts foot traffic, drives strong brand equity and is a key differentiator for retailers competing in both physical and digital marketplaces.

The 4 drivers of consolidated supply chains

Your business thrives on the fast turnaround of complex and rapidly changing orders for a huge variety of customers, produce types and packaging requirements.

The big squeeze: opportunities and challenges facing the fresh produce industry

There’s never been a more exciting time to be a Repacker.

You’re already operating a large Repack business that is taking advantage of new growth opportunities created by more sophisticated consumers, new technologies and converging supply chains.

But you know that to survive, thrive and get ahead of competitors, you’ll need to transform your business to become more agile, profitable and responsive.

Fruit Logisitica 2017 - What's happening at the Compac booth

We’re looking forward to seeing many of you in Berlin this year at Fruit Logistica 2017.

You’ll find us in hall 5.1, Stand A-12.

We are proud to introduce some key members of our team who will be at there to meet on the stand. Among them are our CEO Mike Riley, CTO Ken Moynihan as well as Darrell Smithson, our VP of Global Service and Perry Sansom, the VP of Product and Marketing.

Fruit for future generations – sustainability is great for business

Businesses across the globe are focusing on sustainable practices as a cornerstone for future growth. Building efficiency, minimizing waste and maximizing resources are time-tested business methodologies which are taking on new meaning as the state of our planet’s health becomes clearer.

Make the most of exhibiting at a tradeshow (top 10)

When your company exhibits at a tradeshow it’s an investment both financially and of valuable resources. To ensure you get the most from this investment it pays to do your research and fully utilize the opportunity.

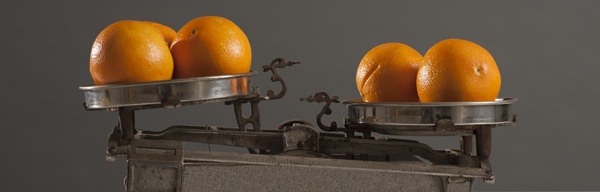

New technology to improve your weighing accuracy

One of the core functions of a packhouse is the accurate and precise weighing of produce for subsequent packing and distribution. Modern packhouses commonly utilize electronic sorting equipment to increase throughput and reduce costs. Within your packhouse, having an accurate, precise set of “weighing scales” is critical to ensure maximum yield through minimized giveaway, and to protect your brand by guaranteeing that every bag meets your customer's target weight requirements.